Leveraging Artificial Intelligence in Gas Sensing

Artificial Intelligence (AI) is being applied in many exciting ways. Most everyone has heard about the big things, like computers that can beat humans at chess, Google image search engines, and “big data.” However, many companies and researchers are using AI in a myriad of ways to improve our lives, including applications in air quality and gas sensing.

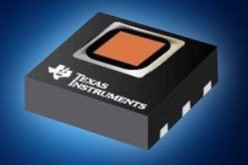

AI can be used to help interpret the response of gas sensors, adding much more value to the information reported by the sensors. The idea is that an array of discreet sensors, or a single sensor that can emulate an array of sensors (such as the ZMOD4410) can be used to produce a set of responses as a function of the environment. Machine learning using neural networks is then used to interpret response patterns and fit a non-linear model in multiple dimensions, which may or may not be obvious to human interpretation. The neural network training can be supervised or unsupervised, depending on the source of the data and whether human judgment is used to label data and add insights, or if the computer is left to find patterns on its own.

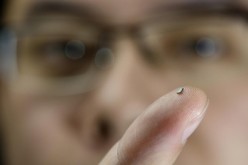

Machine learning requires vast amounts of sensor data collection, characterization, and training under many different conditions. Given the complexity and resources required to realize machine learning solutions with gas sensors, it is possible to provide pre-trained supervised neural network models as a part of algorithms, which can run on a wide variety of low complexity microcontrollers, resulting in a hassle-free solution to the consumer. This is referred to as embedded AI.

There are many interesting examples of how AI can be used to advance applications in gas detection. In one example, characterization of a sensor under a variety of conditions can be used to improve an indoor air quality sensor detecting total volatile organic compound (TVOC). In this case, the neural network model is trained to focus on the features of interest (TVOC) and ignore any minor environmental effects that are not of interest (drift, humidity, etc.).

In a second example, machine learning could be used to add selectivity to gas sensors. For example, a gas sensor can already be used to trigger ventilation in kitchens and bathrooms as a function of odor intensity. With the addition of selectivity, the ventilation could be set to turn on at a lower intensity threshold when the odor falls into a category that is labeled “bad.” When using AI techniques for selective sensors, it is critical that the selective categories defined during the training process encompass the expected use case. For example, a sensor which was trained to detect sulfur as a “bad” smell might not automatically recognize other non-sulfur VOCs as bad smells. However, once the approach is defined and implemented, new features and the ability to recognize new odors can be potentially added with additional training and firmware updates.

This is a really exciting time to be working in sensors and we look forward to seeing what’s next in AI applications and seeing solutions that continue to improve our ability to sense and control our environments.

Author: Debra Deininger – Director of Industrial Sensing