Automotive Engineering Fundamentals

Ever wondered how sophisticated modern vehicles are today? Let’s look at some fundamental concepts to understand our trusted chariots better. Through this section, we will look at the basics such as vehicle architecture, powertrain design, chassis and suspension systems, brakes, and steering.

Vehicle Architecture

Vehicle architecture refers to the design and layout of the various components that make up a vehicle, including the chassis, body, powertrain, suspension, steering, braking, and electrical systems. It involves the arrangement of these components in a way that optimizes the performance, safety, and efficiency of the vehicle.

Vehicle architecture can be subdivided into several categories, such as platform architecture, powertrain architecture, and electrical architecture. Platform architecture refers to the basic structure of the vehicle, including the chassis, body, and suspension. Powertrain architecture refers to the design of the engine, transmission, and drivetrain, while electrical architecture refers to the layout of the vehicle’s electrical and electronic systems.

The choice of vehicle architecture can have a significant impact on the vehicle’s performance, safety, and cost. Different architectures may be better suited for different types of vehicles, such as passenger cars, trucks, and buses, or for different power sources, such as gasoline, diesel, electric, or hybrid. Therefore, designing the optimal vehicle architecture is a critical aspect of vehicle development.

For example, Tata Motors’ Nexon is a subcompact SUV that has a monocoque structure with an integrated chassis and body frame. Whereas a Mahindra Thar is a compact SUV with a ladder-on-frame construction, which is suitable for off-road driving.

Powertrain Design

The powertrain is responsible for converting the energy stored in fuel into mechanical motion to propel the vehicle.

The powertrain typically consists of the engine, which produces power through the combustion of fuel and air; the transmission, which controls the speed and torque of the engine and transfers power to the drivetrain; and the drivetrain, which includes the axles, differential, and wheels that turn the vehicle’s wheels.

The design of the powertrain is critical to the performance and efficiency of the vehicle. Automotive Engineers balance factors such as power output, fuel economy, emissions, durability, and cost to create a powertrain that meets the requirements of the vehicle and its intended use. For example, a high-performance sports car may require a powerful engine with a high horsepower output, while a fuel-efficient commuter car may require a smaller, more efficient engine.

Powertrain design is also impacted by advances in technology and changing consumer demands. With the emergence of electric and hybrid vehicles, powertrain design is increasingly focused on electric motors and batteries, and the integration of software and electronics to manage the powertrain and optimize performance.

In your neighbourhood you might have noticed a Maruti Suzuki Swift, it is a hatchback car with a four-cylinder petrol engine. Whereas Mahindra Electric’s eVerito is a fully electric sedan that has an electric motor.

Chassis and Suspension Systems

The chassis and suspension system are two important components of a vehicle that work together to provide a stable and comfortable ride.

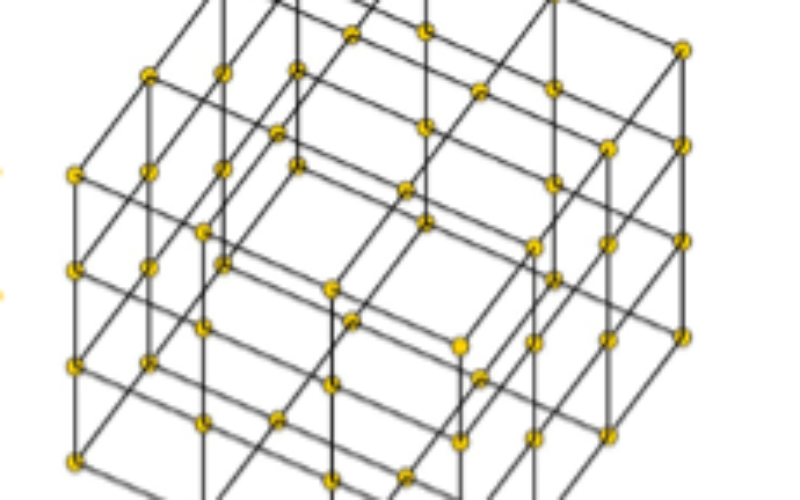

The chassis is the frame of the vehicle that supports all the other components, including the engine, transmission, suspension, and body. It is responsible for providing structural rigidity and strength, as well as for supporting the weight of the vehicle and its passengers. Chassis design and materials are critical factors in determining a vehicle’s overall performance, durability, and safety.

The suspension system, on the other hand, is responsible for absorbing shocks and vibrations from the road, and for maintaining stability and control of the vehicle. It consists of a combination of springs, shock absorbers, and other components that work together to provide a smooth and comfortable ride while keeping the vehicle stable and safe. Suspension design and tuning can have a significant impact on a vehicle’s handling, ride quality, and performance.

There are several types of suspension systems, including independent suspension and solid axle suspension. Independent suspension allows each wheel to move independently, providing better control and handling, while solid axle suspension connects the two wheels on each axle, providing better stability and load-carrying capacity.

Brakes & Steering

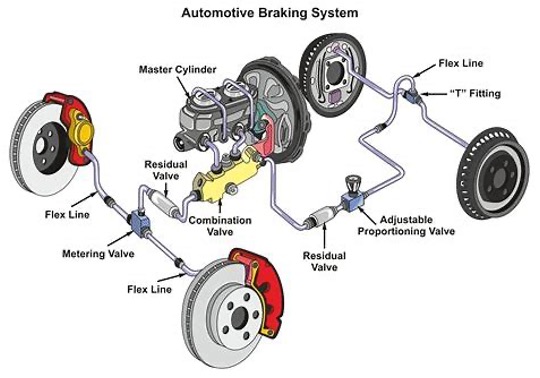

The braking system is a critical component of a vehicle that is responsible for slowing down and stopping the vehicle. It is a safety system that enables the driver to control the speed of the vehicle and bring it to a stop when necessary.

The braking system consists of several components, including the brake pedal, brake lines, master cylinder, brake calipers, rotors or drums, and brake pads or shoes. When the driver presses the brake pedal, hydraulic pressure is generated in the brake lines, which activates the master cylinder. The master cylinder then sends hydraulic pressure to the brake calipers or wheel cylinders, which in turn applies pressure to the brake pads or shoes against the rotors or drums, causing the vehicle to slow down or stop.

There are several types of braking systems, including disc brakes and drum brakes. Disc brakes are more common on modern vehicles and consist of a rotor and calliper that clamp down on the rotor to slow down the vehicle. Drum brakes are typically found on older vehicles and consist of a drum and shoes that press against the inside of the drum to slow down the vehicle.

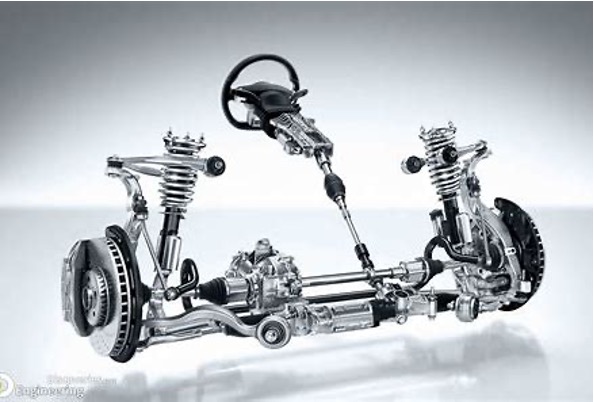

The steering system of a vehicle is responsible for allowing the driver to control the direction of the vehicle. It enables the driver to turn the vehicle left or right and to keep it moving in a straight line.

There are several components in a typical steering system, including the steering wheel, steering column, steering gearbox or rack and pinion, tie rods, and steering arms. When the driver turns the steering wheel, it rotates the steering column, which is connected to the steering gearbox or rack and pinion. The gearbox or rack and pinion then convert the rotation of the steering wheel into lateral movement, which is transmitted to the tie rods. The tie rods are then connected to the steering arms, which turn the wheels left or right, depending on the direction of the steering wheel input.

There are several types of steering systems, including manual steering and power steering. Manual steering requires the driver to turn the steering wheel using physical effort, while power steering uses hydraulic or electric assistance to make steering easier. Power steering is more common on modern vehicles and provides a smoother and more responsive steering feel.

For more interesting content visit yellowmatrix.in