Rather than using supercapacitor technology, which the firm decided is too leaky, it went for a lithium ion electro-chemical system -like a phone battery but modified to extend cycle-life, broaden temperature range, reduce self-discharge, and raise power delivery.

Rather than using supercapacitor technology, which the firm decided is too leaky, it went for a lithium ion electro-chemical system -like a phone battery but modified to extend cycle-life, broaden temperature range, reduce self-discharge, and raise power delivery.

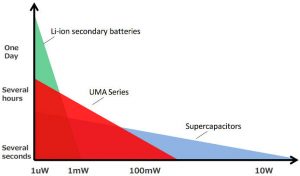

To get these improvements, Murata sacrificed energy capacity, but claims energy/volume remains 40x higher than its own supercapacitors.

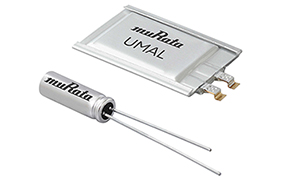

The first product based on the concept, a cylindrical device called UMAC (see photo), was released in October last year. Now an improved device has been announced: prismatic in shape and called UMAL.

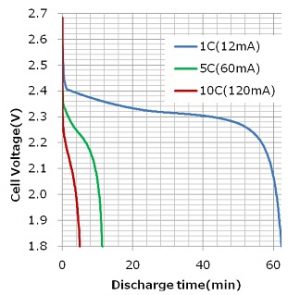

UMAL stores 12mAh, has 200mΩ internal resistance, can be discharged up to 120mA (10C rate) and retains at least 90% of its initial capacity after 5,000 charge-discharge cycles.

It is also, following demand for a thin device said Murata, only 2mm thick compared to the 4mm diameter of UMAC.

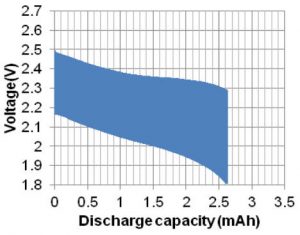

Being an electro-chemical energy store, is has a reasonably flat voltage characteristics and can supply circuits that can work from a nominal 2.3V directly, without a dc-dc converter.

The disadvantage of this flat characteristic is that remaining capacity is difficult or impossible to estimate from terminal voltage – in supercapacitors, remaining energy can easily be predicted from terminal voltage – but the same wide variation in voltage is why they often require dc-dc converters.

Technology

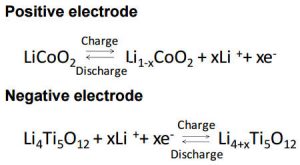

At the negative electrode – lithium titanate replaces the carbon or graphite used in phone batteries.

Li4Ti5O12 does not have the extra-low reaction threshold achieved by carbon or graphite, which means the Murata cell has a lower cell voltage and therefore less energy per mAh, but a moderate reaction threshold increases cell life because the electrolyte is under less stress. It also increases current capability because the resulting ‘solid electrolyte interface’ (SEI) layer on the negative electrode is thinner (therefor less resistive) and traps fewer Li-ions. “As a result, a battery can get high temperature endurance and good cycle characteristic,” said Murata.

Li4Ti5O12 does not have the extra-low reaction threshold achieved by carbon or graphite, which means the Murata cell has a lower cell voltage and therefore less energy per mAh, but a moderate reaction threshold increases cell life because the electrolyte is under less stress. It also increases current capability because the resulting ‘solid electrolyte interface’ (SEI) layer on the negative electrode is thinner (therefor less resistive) and traps fewer Li-ions. “As a result, a battery can get high temperature endurance and good cycle characteristic,” said Murata.

Why is the prismatic UMAL better than the cylindrical UMAC?

“Because the stress on electrode in layered structure is smaller than that of cylinder type and because external terminals contacting each electrode of stacked layers can collect more electricity,” said the firm.

Murata positions the UMA stores above conventional small Li-ion cells on power delivery, and above supercapacitors on energy/volume.

Murata positions the UMA stores above conventional small Li-ion cells on power delivery, and above supercapacitors on energy/volume.

“For example, driving a small motor needs tens of mA. A general small lithium ion battery of the similar size cannot provide such high current and cannot drive the motor,” it said. “On the other hand, a supercapacitor of the similar size can drive it for short time. However, it cannot drive it for a long time because of its low capacitance.”

Power delivery examples:

UMAC

- 0.75W for 40ms

- 6mW for 1.2h

- 60µW for 138h

UMAL

UMAL

- 3W for 280ms

- 100mW for 1.0h

- 6mW for 5.3h

Self-discharge

Self-discharge rates have been calculated from terminal voltage over time after full charge at 25°C as ~200nA in the cylindrical UMAC and ~500nA in the prismatic UMAL.

UMAC

- >80% energy retained after 90 days at 25°C

- >50% after 90 days at 70°C

UMAL

- >90% after 90 days at 25°C

- 75% after 90 days at 70°C

Quick-charge

There is no way to quick-charge the type of Li-ion cells used in phones. Maximum safe constant current charge gets them 80% full in about an hour (this is where some so-called ‘fast chargers’ terminate), and follow-up constant voltage charging fill the remainder over then next two hours. Attempts to speed this result in vastly reduced cycle life, or fire.

UMA cells can be charged at extreme rates without damage, or with minimal damage, and they can be charges from a constant voltage supply without constant current control – simplifying the charge circuit considerably.

“When charging UMAC by constant voltage charge, over 90% of total capacity is charged in five minutes. When charging UMAL, over 95% of total capacity is charged in five minutes,” said Murata.

Float charge

Float charging – leaving a permanent fixed charging potential across a storage device is electrically simple and is possible with supercapacitors and Pb-acid batteries.

It is not possible with conventional Li-ion cells at the rated constant-voltage charging voltage (4.2V for phone batteries), although some researchers maintain is it possible at lower voltages under certain temperature conditions.

Murata’s UMA technology can be float charged.

Maintaining 2.7V on the terminals of a UMAC cell results in virtually no discernible change in capacity after 1,000 hours at 0 or 25°C, although this is no longer true at higher temperatures, and 20% of capacity can be permanently lost after floating for 700h at 70°C.

The prismatic version is far better in this respect, and remarkable for a Li-ion technology. even at 70°C has 99% of its initial capacity after 1,000 hours.

Cycle life

Cycle life is dramatically better than conventional Li-ion cells.

Charging and discharging at 0.5C, the firm got 400 cycles to 80% capacity from a conventional Li-in cell. Something like 600 cycles is expected from phone and laptop batteries.

Compared with this, Murata got over 4,000 cycles from a UMAC cell, despite an incredibly high 33C charge rate (100mA into 3mAh) and 1C discharge.

Low temperature

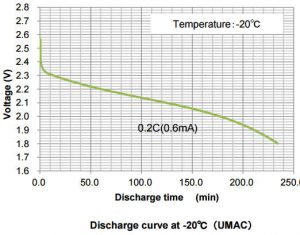

Conventional Li-ion cells cannot safely be charged below 0°C, while the UMAC cell, for example, can safely be charged at 3mA at -20°C. At 0°C, UMA devices are not far off their 25°C performance.

Conventional Li-ion cells cannot safely be charged below 0°C, while the UMAC cell, for example, can safely be charged at 3mA at -20°C. At 0°C, UMA devices are not far off their 25°C performance.

Discharge at -20°C is possible. “Compared to conventional lithium ion batteries, UMA series can charge-discharge higher power even at low temperatures,” said Murata.

The curves above and opposite show UMAC discharged by 600μA continuously, and discharged in repeated heavy (10C, 30mA) 10msec pulses separated by 15s rests.

The curves above and opposite show UMAC discharged by 600μA continuously, and discharged in repeated heavy (10C, 30mA) 10msec pulses separated by 15s rests.

Deep discharge

Deep discharge is generally the end of a phone-type Li-ion cell, which is why circuits are added to stop this happening.

Because aluminium can be used with the lithium titanate electrode instead of the copper needed by graphite electrodes, said Murata, there is no formation of copper precipitate short-circuits and the cells can be left discharge for long periods and, despite some deterioration, can still be re-charged. “Even if this case occurs several times in one year, UMA series can be charged again up to dozens of times,” said the firm.

Safety

As many prople have discovered, phone and laptop Li-ion cells have a thermal run-away characteristic, and once initiated there is no stopping the exothermic reaction that occurs. High temperature, crushing, piercing over-voltage and over-current can all kick-off the reaction.

Murata claims the use of chemically stable materials in its Lithium titanate cells means thermal runaway does not occur under many abuse conditions – for example they will not generate smoke or fire even if the terminals are shorted.

Cylindrical (UMAC040130A003TA01)

| Capacity | 3mAh [+/-20%] |

| ESR @1kHz | 800 mΩ [max 960mΩ] |

| Nominal voltage*1 | 2.3V |

| Cut-off voltage*1 | 1.8V |

| Max.continuous discharge current | 30mA |

| Max. charge current | 150mA |

| Operation temperature range | -20℃~+70℃ |

| Storage temperature range | -20℃~+70℃ |

| Size | 4mm dia x 12mm+leads |

Prismatic (UMAL201421A012TA01)

| Capacity | 12mAh [+/-20%] |

| ESR @1kHz | 200 mΩ [max 240mΩ] |

| Nominal voltage*1 | 2.3V |

| Cut-off voltage*1 | 1.8V |

| Max.continuous discharge current | 120mA |

| Max. charge current | 600mA |

| Operation temperature range | -20℃~+70℃ |

| Storage temperature range | -20℃~+70℃ |

| Size | 21x14x2mm +leads |

Murata has gone he extra mile and released the measurement conditions used to create these tables:

Capacity

- Discharge down to 1.8V at 1CA

- Rest for 30sec

- Charge to 2.7V at 1CA. Then charge at 2.7V until current drops to 0.05CA or after 30 minutes

- Rest for 30s

- Measure capacity while discharging down to 1.8V at 1CA

ESR

- Charge to 2.7V at 1CA. Then charge at 2.7V until current drops to 0.05CA or after 30 minutes

- Rest for 30s

- Measure ESR at 1kHz